Prodotti & Servizi - Reflow Oven Volumi Medi

Azienda

I Prodotti

Pick & Place

Reflow Oven

Vapour Phase

Screen Printer

Solder Wave

Selective Soldering

Handling

Automatic Optical Inspection

Materiali di Consumo

Attrezzature

Usati & Occasioni

Galleria Immagini

Contatti

Rappresentanze

Privacy

Forni di rifusione serie BM-W-G2 per medie produzioni

(5-6-7-8 zone ad aria calda forzata top + bottom)

The reason you need BM-W545/645/745/845 G2 Lead-free reflow oven:

a. Mid production requirement in the range of 500-1000pcs/8hours (Take 300x300 PCB as reference)

b. Tough Lead-free requirement

c. Tight space and tight budget.

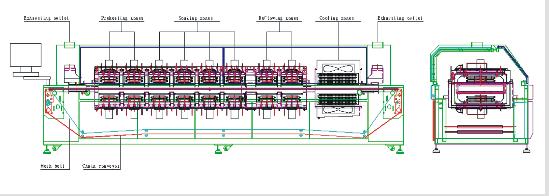

rear door of hood easy opening internal cooling system operator interface panel

l This machine is specially designed for some mid production users.

l Self-developed controller, PC and on-line UPS form a stable, safe and efficient controlling system. The self-developed controller is specially design for the lead-free wave solder machine and lead-free reflow oven. Compare with PLC, it have quicker response, better compatible, more powerful ability for future extension.

l Brand electrical component like Schneider (German) breaker, Panasonic (Japan) speed controller, Omron (Japan) box breaker. Meanwhile the CE certificated blower is specially design for lead-free reflow oven. It runs stable and lower noise. We can provide extra warranty for this great blowers.

l Upper zone and hood can be opened by the electrical screw automatically. It is very convenient for cleaning and maintenance.

l Specially designed Ni-Cr heater filaments, provide a very quick ramp up time. It takes just 15 minutes from ambient to setting temperature.

l The inner tunnel of the oven is made of stainless steel which easy for cleans.

l The entire upper and bottom zones are forced air convection; provide great temperature accuracy and uniform.

l Stainless steel mesh belt and chain conveyor work together.

l In-built industrial chiller provides better cooling performance. Meanwhile, it doesnft need more space.

automatic pin chain lubricator electric cabling

| Items | BM-W545 G2 | BM-W645 G2 | BM-W745 G2 | BM-W845 G2 |

| Heating zones | Upper 5 hot air zones | Upper 6 hot air zones | Upper 7 hot air zones | Upper 8 hot air zones |

| Bottom 5 hot air zones | Bottom 6 hot air zones | Bottom 7 hot air zones | Bottom 8 hot air zones | |

| Heating zone length | 1734mm | 2047mm | 2360mm | 2673mm |

| Overall dimension | L2850*W1020*H1450 | L3163*W1020*H1450 | L3476*W1020*H1450 | L3789*W1020*H1450 |

| Net weight | about 700Kg | about 800Kg | about 900Kg | about 1000Kg |

| General power | 31KW | 37KW | 44KW | 53KW |

| Consumption power | approx.8KW | approx.9KW | approx.11KW | approx.13KW |

| Ramp time | 13 minutes | 15 minutes | 18 minutes | 18 minutes |

| Control type | PC control | |||

| Heat type | Upper zones forced hot air convection+ bottom zones forced hot air convection | |||

| Tem control | PID close-loop,SSR drive | |||

| Temp range | Ambinent-350℃ | |||

| Temp accurancy | ±1 ℃ | |||

| Temp uniform | ±2 ℃ | |||

| Cooling type | In-built industrial chiller provide better cooling performance | |||

| Conveyor type | Stainless steel mesh belt and chain conveyor | |||

| Conveyor height | 900±20mm | |||

| Belt width | 450mm | |||

| Max PCB | 400mm | |||

| PCB clearance | 30mm | |||

| Conveyor direction | Left to right (option: right to left) | |||

| Conveyor speed | 0-1500mm/min | |||

| Hood lift | Electrical screw pole | |||