Prodotti & Servizi - Solder Wave Volumi Alti

Azienda

I Prodotti

Pick & Place

Reflow Oven

Vapour Phase

Screen Printer

Solder Wave

Selective Soldering

Handling

Automatic Optical Inspection

Materiali di Consumo

Attrezzature

Usati & Occasioni

Galleria Immagini

Contatti

Rappresentanze

Privacy

Saldatrice ad onda serie DN per medie-alte produzioni

The reason you need DN-350/400/450/500 Super Lead-free wave solder:

a. Large production requirement in the range of 1200-2200pcs/8hours (Take 300x300 PCB as reference)

b. Lead-free requirement

c. PC control. Solder pot move in&out AND lift up&down Automatically

d. Can upgrade to N2 machine.

e. CE needed.

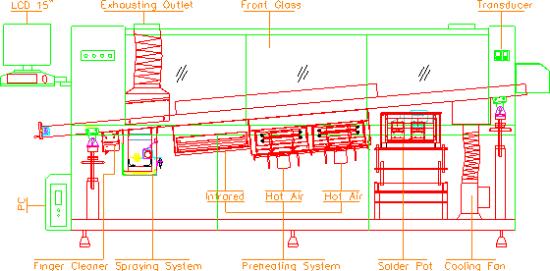

entrance finger conveyor spray fluxer costant pressure system for flux

- A new streamline design replaces a conventional right-angled exterior. And the design

is based on mechanical aesthetics and practicability, making the maintenance an easy job;

- Self-developed controller, PC and on-line UPS form a stable, safe and efficient

controlling system. The self-developed controller is specially design for the lead-free wave

solder machine and lead-free reflow oven. Compare with PLC, it have quicker response,

better compatible, more powerful ability for future extension.

- The software has the functions like PCB counting, temperature setting and editing,

PCB parameter menu, and profile testing, alarms and multi-languages conversion.

In the meanwhile, the software has make a lots effect about the safety issues just like

wave motor running safe temperature, safe power off machine.

- The one-week time will provide a amazing function for customer. The operator can edit

his work schedule for this wave solder machine weekly. And the machine can turn on

automatically to melt the solder before operator come to work. When itfs time to work,

the solder has been melt and everything is ready.

It will save about 1.5 hours for customer everyday.

- The specially designed guiding rail reduce the deformation caused by heat.

- Sprayer droved by German air cylinder, small noise and long life warranty.

- The sprayer is made in Japan; it provides perfect atomization performance of the flux.

- Forced air convection preheat zone control by temperature controller in PID model.

The preheat zone will provide enough uniform heat for the PCB.

- 3 individual bottom hot air zone and third upper hot air zone, this configuration

will provide the greatest preheating effect for soldering.

- Adopt cast iron heater for the solder pot, itfs mounted outside of the solder pot.

This new assembling way will prolong the life of the solder pot.

- Dual wave solder. Both wave heights are controlled by transducer.

Changing the wave height via adjusting the frequency of power.

- Solder pot is made of Ti material. Long life warranty.

- High quality R&M wave motor which made in Italian, small noise and more stable.

- Solder pot can lift up and down, move in and out automatically.

It's very easy for customer to change solder pot and conversion between leaded

and lead-free.

wave motors (long-life) N2 nitrogen feeding system nterface operator panel

profiling system hot air preheater top hot air preheater

interchang. trolley system double titanium nozzles swing nozzle (option)

| Items | DN - 350 | DN - 400 | DN - 450 | DN - 500 |

| PCB width | 30 - 350mm | 30 - 400mm | 30 - 450mm | 30 - 500mm |

| Pot volume | 370 Kg | 390 Kg | 410 Kg | 430 Kg |

| Running/general power | 13Kw / 34Kw | 13Kw / 35Kw | 14Kw / 36Kw | 14Kw / 37Kw |

| Machine dimenssion | L4200 W1400 H1700 | L4200 W1450 H1700 | L4200 W1500 H1700 | L4200 W1550 H1700 |

| Net weight | 1100Kg | 1200kKg | 1300Kg | 1400Kg |

| Controlling system | PC control | |||

| Conveyor motor | 220V 3Ph 90W | |||

| Conveyor speed | 200mm - 1800mm/min | |||

| Flux volume | 6,5 litres (option 25 litres pressure pot) | |||

| Alcohol volume | 4,5 litres | |||

| PCB direction | left to right | |||

| Spray drive | air cylinder drive | |||

| Sprayer | St -6 made in japan | |||

| Preheater | 3 hot air convection zone and third upper hot air zone | |||

| Preheat power | 4Kw/zone | |||

| Solder pot material | Ti | |||

| Solder pot heater | Cast iron heater | |||

| Solder pot power | 1,2 Kw * 10PCS | |||

| Wave number | dual waves | |||

| Wave type | turbulent first wave - lambda second wave | |||

| Time for melt | 60 minutes | |||

| Solder pot upper/down | Automatically | |||

| Solder pot in/out | Automatically | |||

| Finger cleaning pump | 220V 1Ph 10W | |||

| Conveyor type | Ti finger | |||

| Solder angle | 3 - 6° | |||

| Air supply | 3 - 5 BAR | |||

| Power supply | 220V 3Ph 60Hz or 380V 3Ph 50Hz or 440V 3Ph 60Hz | |||